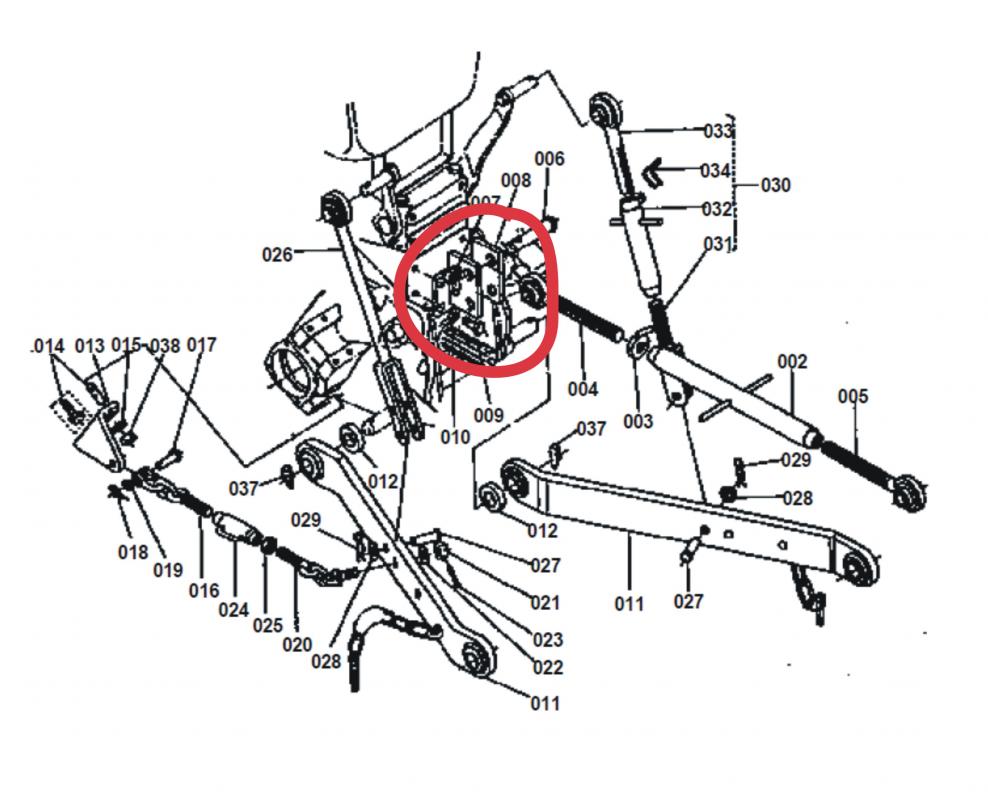

I'm wondering if anyone out there can provide a good picture and measurements of the holder, top link for a L175

Part number is 99511 - 22140

Circled in the picture below.

Unfortunately this item is discontinued, and the salvage yards know it.

Part number is 99511 - 22140

Circled in the picture below.

Unfortunately this item is discontinued, and the salvage yards know it.

Attachments

-

83.4 KB Views: 7,201