Hydraulic tap???

- Thread starter LazyW

- Start date

I have a L1501DT. I want to know what is the best way to tap the hydraulics to add a loader or blade. Thanks for the help. You guys are awesome.

Sent from my SM-G960U1 using Tapatalk

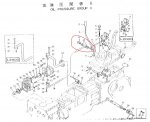

This where my L1500DT is tapped for my loader,

not sure if they are the same or similar....

Attachments

-

94.1 KB Views: 675

-

98.6 KB Views: 620

Yep, that is quite different, I cannot remember who here had a L1501,

possibly Daren Todd? He may chime in?

possibly Daren Todd? He may chime in?

I hope someone can give me information.

Sent from my SM-G960U1 using Tapatalk

Look at this thread to start, both the L185 and L1501 use the same Z751 engine.

.....

https://www.orangetractortalks.com/forums/showthread.php?t=17486

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

By far the easiest way to tap into the hydraulics on these models is to cut the feed line from the pump, putting a fitting on each end of the line.

Then using those two ends to loop to an open center valve with a third line for a return that you will have to pipe into the sump, most use a fill port with an adapter for the return.

You will need to make sure you use a valve with a pressure relief valve in it, or you can deadhead the pump.

Then using those two ends to loop to an open center valve with a third line for a return that you will have to pipe into the sump, most use a fill port with an adapter for the return.

You will need to make sure you use a valve with a pressure relief valve in it, or you can deadhead the pump.

Thanks for the thread link. It's good to know others have made this happen. However my setup is different than the one that is discussed. I don't have a spot for the block that was mentioned.Look at this thread to start, both the L185 and L1501 use the same Z751 engine.

.....

https://www.orangetractortalks.com/forums/showthread.php?t=17486

Sent from my SM-G960U1 using Tapatalk

North Idaho Wolfman could you elaborate more? What type of fittings (compression or welded on) I understand that you interrupt the high pressure line (put the valve in the loop) but where does the return line come from? what type of pressure and gpm are these pumps capable of? Thanks

Sent from my SM-G960U1 using Tapatalk

Sent from my SM-G960U1 using Tapatalk

Darren Todd used to have one. He did a thread where he made the sub frame and tapped into the hydraulic system to put a Massey Ferguson loader on it. I think that it's in the fabrication section.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

The system is a 2500 PSI give or take setup, so high pressure fittings are required, preferably welded on fittings are the best.

The return line comes from the valve and will be taped into the sump of the tractor.

The return line comes from the valve and will be taped into the sump of the tractor.

What gpm does this system work with?The system is a 2500 PSI give or take setup, so high pressure fittings are required, preferably welded on fittings are the best.

The return line comes from the valve and will be taped into the sump of the tractor.

Sent from my SM-G960U1 using Tapatalk

Darren Todd used to have one. He did a thread where he made the sub frame and tapped into the hydraulic system to put a Massey Ferguson loader on it. I think that it's in the fabrication section.

Here is the thread @bucktail may be referring to....

https://www.orangetractortalks.com/forums/showthread.php?t=32751&highlight=Massey+Ferguson

Thanks for the link. What is your opinion about the compression fittings?

Sent from my SM-G960U1 using Tapatalk

Like NIW stated "2500 PSI" possibly a bit much for compression fittings

unless you go with stainless steel.......

https://www.stainlesssteelfittings.com/Compression_Union_U_stainless_p/u.htm?gclid=CjwKCAjw7e_0BRB7EiwAlH-goP9aW056nDSUOQxHqN1AwljQJNJgLY6J125aNBcy3NQ9nqgJnrUoLRoCypgQAvD_BwE

Welded would be ideal, but I would trust a fitting over my welds

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

GPM is in the 3 to 4 range.

The compression fittings of the right type for the PSI would be ok if you can find them to fit the size of pipe, it's normally an odd size and you have more tolerance with welded on fittings.

The compression fittings of the right type for the PSI would be ok if you can find them to fit the size of pipe, it's normally an odd size and you have more tolerance with welded on fittings.