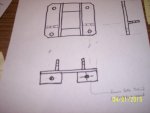

I recently purchased my first tractor, a used B3030. After using the box blade for a little while I noticed that a bolt for the top link mount bracket on the transmission was loose. After a closer examination I discovered that the problem was a lot worse than a loose bolt, see pictures. Does anyone know a fix for this situation other than replacing the transmission casting that's broken? Is there a one piece bracket that could be mounted with just 3 bolts but had enough structural integrity to support the tensions applied by the top link? I was thinking of having something fabricated on a piece of 1/2" steel plate that would provide the same hole patterns for attaching the top link. Please share your thoughts, ideas or concerns. Any ideas what could have caused this to break?

Thanks,

Gary

Thanks,

Gary

Attachments

-

94.9 KB Views: 836

-

91.7 KB Views: 994