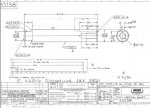

I emailed Woods and asked for a technical drawing of the shaft I need to make. They sent me the prints!

Makes it so much easier to make the part.

Makes it so much easier to make the part.

Attachments

-

18.9 KB Views: 263

-

20.1 KB Views: 275