Maybe there's a kubota using this gas engine. I have adjusted valves per the manual. After they are adjusted I can turn the engine and the valve lash opens up. With the valves adjusted per manual, there is 0 compression. If I adjust vales to what I consider the bottom of the lobe, still no compression. If I back the adjusters all the way open I get 130lb. Is this cam wore out, slipped in gear,or am I stupid!

Kawasaki fx921v valve adjustment.

- Thread starter Muggman

- Start date

Not stupid. The compression release is on the cam. 100% sure it's TDC? Kawasaki's in general have this issue. The release is either an extra "lo e" (the missing letter is inop on pc.), or a governor of sorts. Never into specific engine to know 100%

Every cam I've seen has the comp. Release closest to cam gear. On a vertical shaft that would be lowest valve on lowest cyl. I don't have a dial indicator and magnetic base anymore or I would profile the cam. Engine only has 600 hours. I can't find a good picture to look at it.

Pretty straight forward on mine.

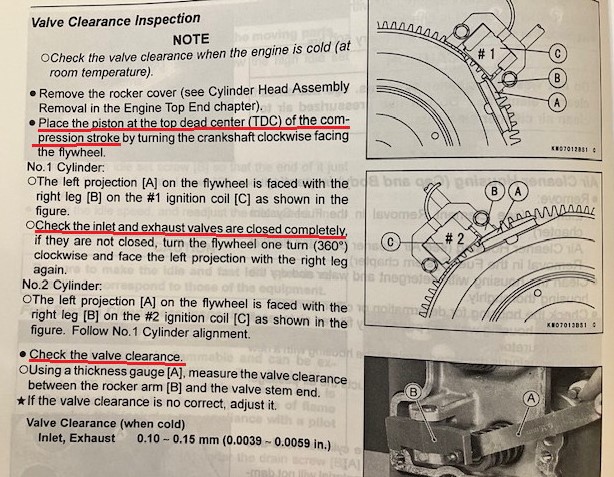

Make sure you are at TDC on the compression stroke.

Make sure you are at TDC on the compression stroke.

^^^^It's a v-twin. I was under the assumption that the compression release was on the exhaust valve on cylinder #2. I'm working on #1. I have compression with about .030

Lash,but it don't sound good.

I bet it doesn't sound good. That would be a good spark plug gap!

We want between .004 and .006 (thousandths) clearance.

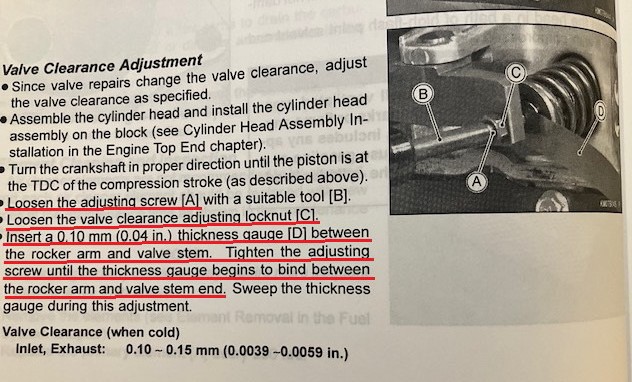

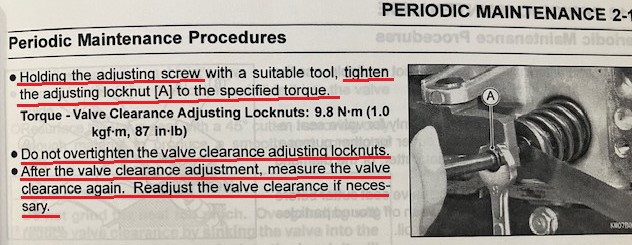

the springs are really weak. When you stuff a thickness gauge between the valve stem and rocker arm, you just barely want any drag-no more. It's not a race engine that has 400 lbs of spring pressure on the seat, so if you are too overzealous with adjusting, you can actually push the valve open a little and stray your clearance measurement.

also on all of the V-twin kawi's (and a lot of subaru/kubota and yamaha and honda and kohler) engines, I like to turn the engine til it's at TDC on the compression (not overlap) stroke, then go just a little bit further past TDC (after TDC). The valves are guaranteed closed because we don't want them open as combustion is occurring. Some of the Kohlers you have to do do it this way because the ACR will hold the valve open until almost TDC, which plays with the lash measurement. So you have to go past but not very much-like 10-15 degrees of crank rotation max.

Finally, on some of the kawi's they had issues with the rocker studs pulling out of the head and/or being loose....which will mess with your adjustment procedure. I don't remember which ones specifically but I remember doing a few of them with loose studs.

also on all of the V-twin kawi's (and a lot of subaru/kubota and yamaha and honda and kohler) engines, I like to turn the engine til it's at TDC on the compression (not overlap) stroke, then go just a little bit further past TDC (after TDC). The valves are guaranteed closed because we don't want them open as combustion is occurring. Some of the Kohlers you have to do do it this way because the ACR will hold the valve open until almost TDC, which plays with the lash measurement. So you have to go past but not very much-like 10-15 degrees of crank rotation max.

Finally, on some of the kawi's they had issues with the rocker studs pulling out of the head and/or being loose....which will mess with your adjustment procedure. I don't remember which ones specifically but I remember doing a few of them with loose studs.

I've tried it several different was. I've set the intake with the exhaust half open. Set the intake with the exhaust open. I've even turned the engine, found the low spot on cam and set lash there, but then I have no compression. It's like the cam is flat on the back side of the lobe. I wasn't the first one to try to set them. Wish I could have started from the factory setting. How many threads are usually showing above locknut on rocker arms?the springs are really weak. When you stuff a thickness gauge between the valve stem and rocker arm, you just barely want any drag-no more. It's not a race engine that has 400 lbs of spring pressure on the seat, so if you are too overzealous with adjusting, you can actually push the valve open a little and stray your clearance measurement.

also on all of the V-twin kawi's (and a lot of subaru/kubota and yamaha and honda and kohler) engines, I like to turn the engine til it's at TDC on the compression (not overlap) stroke, then go just a little bit further past TDC (after TDC). The valves are guaranteed closed because we don't want them open as combustion is occurring. Some of the Kohlers you have to do do it this way because the ACR will hold the valve open until almost TDC, which plays with the lash measurement. So you have to go past but not very much-like 10-15 degrees of crank rotation max.

Finally, on some of the kawi's they had issues with the rocker studs pulling out of the head and/or being loose....which will mess with your adjustment procedure. I don't remember which ones specifically but I remember doing a few of them with loose studs.

I think the lobes are bad on cam. I think some of these engines had head and cam recalls.I've tried it several different was. I've set the intake with the exhaust half open. Set the intake with the exhaust open. I've even turned the engine, found the low spot on cam and set lash there, but then I have no compression. It's like the cam is flat on the back side of the lobe. I wasn't the first one to try to set them. Wish I could have started from the factory setting. How many threads are usually showing above locknut on rocker arms?

^^^^^^Finally, on some of the kawi's they had issues with the rocker studs pulling out of the head and/or being loose....which will mess with your adjustment procedure. I don't remember which ones specifically but I remember doing a few of them with loose studs.

Several models in the past. Most due to excessive heat in the heads, because folks would not clean the cooling fins and debris would build up.

A 89 yr. Old retired air force airplane mechanic owns this mower. He still uses and keeps the service up, but too old too still work on it.^^^^^^

Several models in the past. Most due to excessive heat in the heads, because folks would not clean the cooling fins and debris would build up.

Understand. Thank You for trying to help him with it.A 89 yr. Old retired air force airplane mechanic owns this mower. He still uses and keeps the service up, but too old too still work on it.

I shoot for .004 on the intake and .006" on the exhaust since it gets hotter and parts expand a bit more.

Not sure what the issue is. But bringing the engine around to TDC (on the compression stroke) should result in both valves being closed and the rocker arms 'loose' so that you slip a feeler gauge between the parts.

setting lash using EOIC method only works when a ACR is not used.

Engines that have ACR you have to do it AT or just past TDC, or your settings are almost guaranteed to be off.

Engines that have ACR you have to do it AT or just past TDC, or your settings are almost guaranteed to be off.

Understand. Thank You for trying to help him with it.

I shoot for .004 on the intake and .006" on the exhaust since it gets hotter and parts expand a bit more.

Not sure what the issue is. But bringing the engine around to TDC (on the compression stroke) should result in both valves being closed and the rocker arms 'loose' so that you slip a feeler gauge between the parts.

I think the acr is on cylinder #2. I'm working on cyl #1setting lash using EOIC method only works when a ACR is not used.

Engines that have ACR you have to do it AT or just past TDC, or your settings are almost guaranteed to be off.

If I disregard piston position totally and turn the engine till the rocker arm is at its loosest, and then tighten down to .004 on the intakes I should be able to atleast run it. Not the case. I firmly beleave its a cam issue. I'm taking it to a dealer after I clean it up. Got new gaskets on the way. I'm going to do a follow up on it with y'allUnderstand. Thank You for trying to help him with it.

I shoot for .004 on the intake and .006" on the exhaust since it gets hotter and parts expand a bit more.

Not sure what the issue is. But bringing the engine around to TDC (on the compression stroke) should result in both valves being closed and the rocker arms 'loose' so that you slip a feeler gauge between the parts.

OK FOUND OUT I AM STUPID. After looking at the engine today I realized this engine loads from the top instead of like a briggs. That means the cam gear is up top I guess and #1 is the ACR cylinder. That would explain the no compression on #1. Wish someone would have told me. I am now going back to the manual and start completely over. It seems to be blowing air out the pushrod hole, but at least I have a new plan.If I disregard piston position totally and turn the engine till the rocker arm is at its loosest, and then tighten down to .004 on the intakes I should be able to atleast run it. Not the case. I firmly beleave its a cam issue. I'm taking it to a dealer after I clean it up. Got new gaskets on the way. I'm going to do a follow up on it with y'all

I ended up taking this mower to another mechanic. This is what I was told by him. He stated that he had to pull both heads and that the exhaust valve stems were heavily coated with carbon, to the point that the valves weren't closing. They replaced the exhaust valves. Haven't picked it up yet. May be more to the story.OK FOUND OUT I AM STUPID. After looking at the engine today I realized this engine loads from the top instead of like a briggs. That means the cam gear is up top I guess and #1 is the ACR cylinder. That would explain the no compression on #1. Wish someone would have told me. I am now going back to the manual and start completely over. It seems to be blowing air out the pushrod hole, but at least I have a new plan.

as I said, the springs are VERY weak and they won't close the valve with enough force clean off carbon buildup from the valve stems.I ended up taking this mower to another mechanic. This is what I was told by him. He stated that he had to pull both heads and that the exhaust valve stems were heavily coated with carbon, to the point that the valves weren't closing. They replaced the exhaust valves. Haven't picked it up yet. May be more to the story.

^^^^^^I ended up taking this mower to another mechanic. This is what I was told by him. He stated that he had to pull both heads and that the exhaust valve stems were heavily coated with carbon, to the point that the valves weren't closing. They replaced the exhaust valves. Haven't picked it up yet. May be more to the story.

If that was the case then hopefully they disassembled the heads, cleaned the intake valves, lightly 'lapped' them back in and replaced all the valve stem seals. Valve spring specs can be checked while the head is apart, but easier to just replace if they were thought to be weak.

I have a bit over 1K hours on my FX921V with no issues......but will pull the heads and rebuild them at about 1200 hrs, just for maintenance sake.

If it had that much carbon, there is 100% a cause. Either the air filter is letting stuff by, it's running very rich, bad gas, burning oil. Either HG or bad rings. Or some combo of them.