Looking for some advice on front mounted ball hitch for Kubota LX3310. I am parking quite a few items in a large cold storage building and need to be going forward so I can see and placing things pretty precisely.

I see they make some simple ones that clamp to a bucket and also some that slide on one or both pallet forks. I could see the pallet fork version giving lots of reach, but also giving up lift capacity. I will be moving a couple fairly large flat beds and a 26' camper. Depending on how it's loaded, the camper has a tongue weight of at least 400-500 pounds.

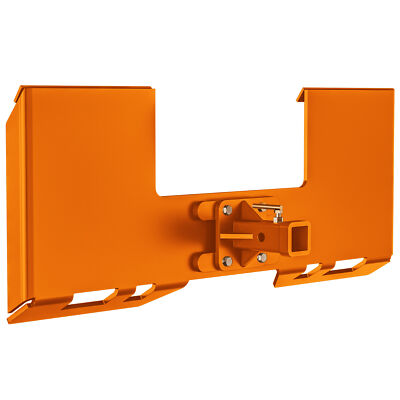

I also see a more expensive style that goes right on the SSQA so sits close to the front of the loader. Quite a bit more money, but would retain loader lift capacity and likely more tractor stability than a heavy load at the far end of pallet forks.

Interested in experiences and advice you would have.

Thank You!

I see they make some simple ones that clamp to a bucket and also some that slide on one or both pallet forks. I could see the pallet fork version giving lots of reach, but also giving up lift capacity. I will be moving a couple fairly large flat beds and a 26' camper. Depending on how it's loaded, the camper has a tongue weight of at least 400-500 pounds.

I also see a more expensive style that goes right on the SSQA so sits close to the front of the loader. Quite a bit more money, but would retain loader lift capacity and likely more tractor stability than a heavy load at the far end of pallet forks.

Interested in experiences and advice you would have.

Thank You!