Hello all, first post on this site and I have asked this question on other sites but no answers in over a week so I found this site and read thorugh hundreds of pages over the last few days and still have not found my answer so I will ask and hopefully get some answers.

Can anyone tell me what the 3 screws that are capped off near the injection pump are on my D1105? I have attached a pic for reference. I know they are screws for adjusting the governor/fuel delivery, but what does each one specifically control? How does adjusting one affect the other, or is there no correlation between them. I ask because I have ordered a turbo kit for my RTV X1140 and reading the different install instruction from different designs from different companies to get a handle what I am going to be doing, some say adjust this one and that one and another says adjust this one etc., but none of the instructions tell you why or what to expect. They just say move it 1-2 turns and tighten or make the bolt 0.625" from the nut. I want to know what each specifically does so I know what to expect while tuning this thing. Detailed info and explanations would be appreciated!

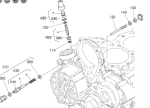

I should clarify that I am looking specifically at parts #20, #65, and #120. Each different turbo kit says something different in thier install manuals. I'm sure not all turbo kits are exactly the same but I would expect the tuning process to be similar and from what I read, they are not similar in tuning. I can't see why one would say to do this screw and not the next one, and another says to adjust this one and not the 2 the other mentioned by the other manufacturer. Just trying to understand the cause/effect of adjusting each one. Same goes for the tamper proof torx screws on the injector pump delivery plates. In one set of instruction they say to loosen the injector plates and rotate the plates counterclockwise as far as they will go. What does this do? I assume it will increase fuel in some way but other instructions do not mention this at all. Just trying to piece this all together in my head and use some instructions from all the different options together if needed. I just can't imagine why the tuning instructions are so much different.

I have already installed EGT, Boost, Air Intake Temp gauges, etc. to aid in tuning but don't feel comfortable doing my install yet until I figure out what I am really adjusting while I am tuning it. Yea, I can adjust and test and figure out what these screws do, but I would rather not waste the time and know ahead of time what they do. Hope someone can explain this. Thanks!

Can anyone tell me what the 3 screws that are capped off near the injection pump are on my D1105? I have attached a pic for reference. I know they are screws for adjusting the governor/fuel delivery, but what does each one specifically control? How does adjusting one affect the other, or is there no correlation between them. I ask because I have ordered a turbo kit for my RTV X1140 and reading the different install instruction from different designs from different companies to get a handle what I am going to be doing, some say adjust this one and that one and another says adjust this one etc., but none of the instructions tell you why or what to expect. They just say move it 1-2 turns and tighten or make the bolt 0.625" from the nut. I want to know what each specifically does so I know what to expect while tuning this thing. Detailed info and explanations would be appreciated!

I should clarify that I am looking specifically at parts #20, #65, and #120. Each different turbo kit says something different in thier install manuals. I'm sure not all turbo kits are exactly the same but I would expect the tuning process to be similar and from what I read, they are not similar in tuning. I can't see why one would say to do this screw and not the next one, and another says to adjust this one and not the 2 the other mentioned by the other manufacturer. Just trying to understand the cause/effect of adjusting each one. Same goes for the tamper proof torx screws on the injector pump delivery plates. In one set of instruction they say to loosen the injector plates and rotate the plates counterclockwise as far as they will go. What does this do? I assume it will increase fuel in some way but other instructions do not mention this at all. Just trying to piece this all together in my head and use some instructions from all the different options together if needed. I just can't imagine why the tuning instructions are so much different.

I have already installed EGT, Boost, Air Intake Temp gauges, etc. to aid in tuning but don't feel comfortable doing my install yet until I figure out what I am really adjusting while I am tuning it. Yea, I can adjust and test and figure out what these screws do, but I would rather not waste the time and know ahead of time what they do. Hope someone can explain this. Thanks!

Attachments

-

116.1 KB Views: 124

-

891.8 KB Views: 115

-

1.1 MB Views: 87

-

1.1 MB Views: 79