I have a bad leak between my front wheel drive bevel gear case and front gear case. I have removed everything and cannot separate the bevel gear case from the front gear case. It seems the bevel gear case tube extends into the front gear case where a bearing is on the tube. They start to separate about 1/4" then it sticks. Must it be pressed off? The manual says tap the case to separate but I have tapped the heck out of it and only get 1/4".

L3130 bevel gear case

- Thread starter randy c

- Start date

If you're talking about the tube that covers the propeller shaft between the transmission and the front end, there are one or two screws in the side of the tube toward the middle that hold the tube together and in place. If they are removed, it should take little effort to collapse the tubes.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Yea I think we need better clarity where you are at:

State part group name and then number please.

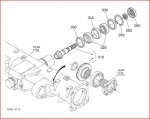

Front Bevel Gear

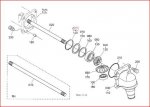

Differential Gear Shaft

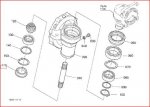

Front Axle Case

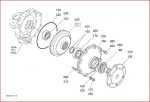

Front Axle

State part group name and then number please.

Front Bevel Gear

Differential Gear Shaft

Front Axle Case

Front Axle

Attachments

-

34.1 KB Views: 6,926

-

32.7 KB Views: 7,673

-

35.9 KB Views: 9,830

-

36.2 KB Views: 11,136

Rentthis, thanks, but I'm talking about another part. Sorry I wasn't clear.

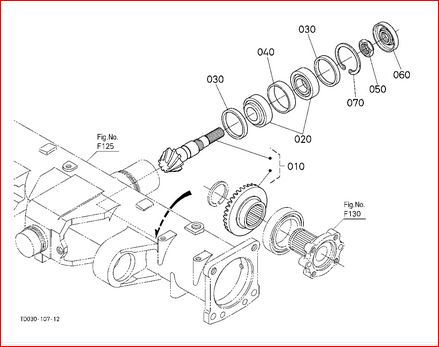

North Idaho Wolfman, the front axle case is where I am. Part no 20/front axle case and fig 145/bevel gear case are stuck together with parts 050/seal and 060 bearing still in there. I can pry them apart with screwdrivers and knock them back and forth with a rubber hammer but only 1/4". I even hit the tube part with a brass drift. It will move no further. It is soaking in Kroil.

North Idaho Wolfman, the front axle case is where I am. Part no 20/front axle case and fig 145/bevel gear case are stuck together with parts 050/seal and 060 bearing still in there. I can pry them apart with screwdrivers and knock them back and forth with a rubber hammer but only 1/4". I even hit the tube part with a brass drift. It will move no further. It is soaking in Kroil.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Did you remove snap ring #70?

If you did, it's just a matter of the right thump.

On the front axle case rotate it side to side while thumping on the top and the back bottom (outward) of the front axle case, use a dead blow hammer.

If you did, it's just a matter of the right thump.

On the front axle case rotate it side to side while thumping on the top and the back bottom (outward) of the front axle case, use a dead blow hammer.

Thanks, Wolfman. I did remove that snapring. It was an external one around the tube that I'm fighting. I guess I'll keep thumping it back and forth. Now I just have to find a dead blow 10Lb maul. I'll let you know what happens.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Clarifying just to make sure:Thanks, Wolfman. I did remove that snapring. It was an external one around the tube that I'm fighting. I guess I'll keep thumping it back and forth. Now I just have to find a dead blow 10Lb maul. I'll let you know what happens.

#70 in an internal snap ring that attaches to the case

#100 is the external that attaches to the tube.

So did you remove both?

Honestly not trying to be a PITA, just trying to make sure because it shouldn't take much force to remove it, In fact most just fall off.

Wolfman, you are correct. I got the external ring off the hollow shaft. The bearing above is sitting on a ledge and must go up. The hollow shaft won't go through the bearing and I cant see split ring 70.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Use a pick tool to pull out the shim (#90) then the bearing (#80) then that should let you see and remove (#70).

Sorry for the delay. I was on another mission yesterday. The shim and bearing were out. The ring is what I thought was the bearing race. The ends must be hidden behind the groove it sits in. I'll try to turn that ring around until the ends appear. I'll do it today. Thanks.

Wolfman, I think I see my problem. The bevel gear case needs to be removed before I can access the seal 50, bearing 60, snap ring 70, and bearing 80. I probably flared the end of the hollow shaft of the bevel gear case when I hit it with a brass drift pin trying to get it out. Now it won't pass through the inner race of bearing 80. Now I think my only shot is to bring it to the dealer and hope they can press it out unless you can think of anything else.

Billdog350

Member

Equipment

Kubota L3710 HST,L2230A QT,forks,Takeuchi TB125, 60" Luck Now pto Snowblower

Why not try to get a dremel or similar up in there and take off the flare? The kubota parts are all cast, there shouldn't be too much that needs to be cleaned up.

If you used a brass drift pin you can't have much of a flare, just dress it with whatever you have. What you been hitting is steel which is the reason for the brass drift....it's softer.

Don't give up so soon!!

Don't give up so soon!!

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Take a couple of pictures of where you are at and what your dealing with and post them here.

I'm pretty sure we all can get you on the right path.

I'm pretty sure we all can get you on the right path.

http://www.orangetractortalks.com/f...ttachmentid=20933&stc=1&d=1457110863457110863

Billdog, I couldn't get a dremel that far in. I tried a small file but it would be a long time.

D2Cat, That's what I thought too but I can see where it's pretty upset wherever I hit it (all around).

If you look at my removal rig, I took a couple of swings with an 8 Lb hammer but the hollow shaft just made a round dent in the 2x4.

Wolfman, I appreciate all your help but I think I may have mistreated that shaft. I brought it to the shop where the guy said he would try to press it out some time today. If he gets it off I will try to work that shaft with a file and emory strips until those bearings slide over the end. The manager acted like they always need to be pressed out but I don't think so. It slides about 1/4 inch before it stops. I'll let you know what happens. Thanks, guys.

Billdog, I couldn't get a dremel that far in. I tried a small file but it would be a long time.

D2Cat, That's what I thought too but I can see where it's pretty upset wherever I hit it (all around).

If you look at my removal rig, I took a couple of swings with an 8 Lb hammer but the hollow shaft just made a round dent in the 2x4.

Wolfman, I appreciate all your help but I think I may have mistreated that shaft. I brought it to the shop where the guy said he would try to press it out some time today. If he gets it off I will try to work that shaft with a file and emory strips until those bearings slide over the end. The manager acted like they always need to be pressed out but I don't think so. It slides about 1/4 inch before it stops. I'll let you know what happens. Thanks, guys.

Attachments

-

55.1 KB Views: 601

-

40.1 KB Views: 464

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Randy,

If you haven't taken it in yet, could you give me a picture of the parts that you removed?

It looks to me like you still have a bearing up in there and therefore you cant get to the next snap ring up.

Note:

If the other snap ring is in there, and a shop tries to press it out, it's very possibly going to do some major damage!

If you haven't taken it in yet, could you give me a picture of the parts that you removed?

It looks to me like you still have a bearing up in there and therefore you cant get to the next snap ring up.

Note:

If the other snap ring is in there, and a shop tries to press it out, it's very possibly going to do some major damage!

Guys, it was harder than I thought. The bevel gear case would not press out. The end of the hollow shaft was flared and would not pass through bearing 80. They had to burn out bearings 80 and 60, take out the bevel gear case and grind off the flare I hammered with what must be the hardest brass punch in the world. If I ever have to do the other side, I will pry it apart at the junction between the two cases. I should have checked with you before I did anything but I didn't know about you until too late. Thanks for the help.